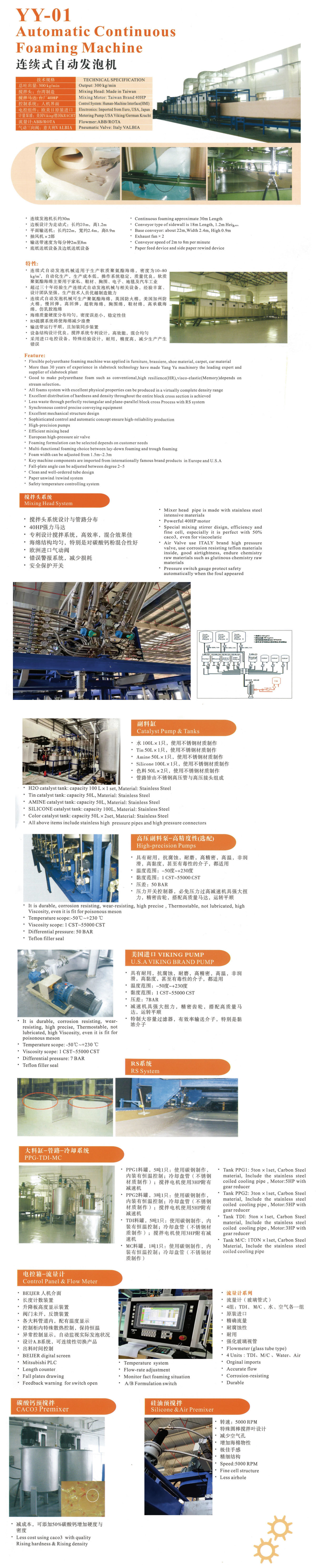

Feature:

●Flexible polyurethane foaming machine was applied in furniture,brassiere,shoe material,carpet,car material

●More than 30 years of experience in slabstock technology have made Yang Yu machinery the leading expert and supplier ofslabstock plant

●Good to make polyurethane foam such as conventional,high resilience(HR),visco-elastic(Memory)depends on stream selection.

●All foams system with excellent physical properties can be produced in a virtually complete density range

●Excellent distribution of hardness and density throughout the entire block cross section is achieved

●Less waste through perfectly rectangular and plane-parallel block cross Process with RS system

●Synchronous control precise conveying equipment

●Excelentmechanicalstructure design

●Sophisticated control and automatic concept ensure high-reliability production

●High-precision pumps

●Efficient mixing head

●European high-pressure air valve

●Foaming formulation can be selected depends on customer needs

●Multi-functional foaming choice between lay-down foaming and trough foaming

●Foam width can be adjusted from 1.5m~2.3m

●Key machine components are imported from internationally famous brand products in Europe and U.S.A

●Fall-plate angle can be adjusted between degree 2~5

●Clean and well-ordered tube design

●Paper unwind/rewind system

●Safety temperature controlling system

The Continuous Automatic Foaming Line is an advanced production system designed for the high-efficiency manufacturing of foamed products. This innovative line integrates automation technology with precision engineering to produce consistent and high-quality foam sheets, panels, and other products used across various industries such as construction, automotive, and packaging.

This foaming line is equipped with multiple stages of automation, including automatic feeding, mixing, molding, and cutting. These stages ensure that the foam is produced without manual intervention, reducing labor costs and increasing production speed. Additionally, the line features advanced temperature control systems that regulate the foaming process, ensuring precise control over the product’s properties such as expansion rate, thickness, and mechanical strength.

Furthermore, the Continuous Automatic Foaming Line is designed with sustainability in mind. Energy-efficient motors, reduced material waste, and optimized production cycles help minimize the environmental impact. The system can be customized to accommodate various raw materials, foam densities, and production rates, offering flexibility to meet the specific needs of different industries.

With its robust build, energy efficiency, and high throughput, the Continuous Automatic Foaming Line is a state-of-the-art solution for companies looking to streamline their foam production processes while maintaining product quality and reducing operational costs.

YY-01 continuous automatic foaming machine

Category