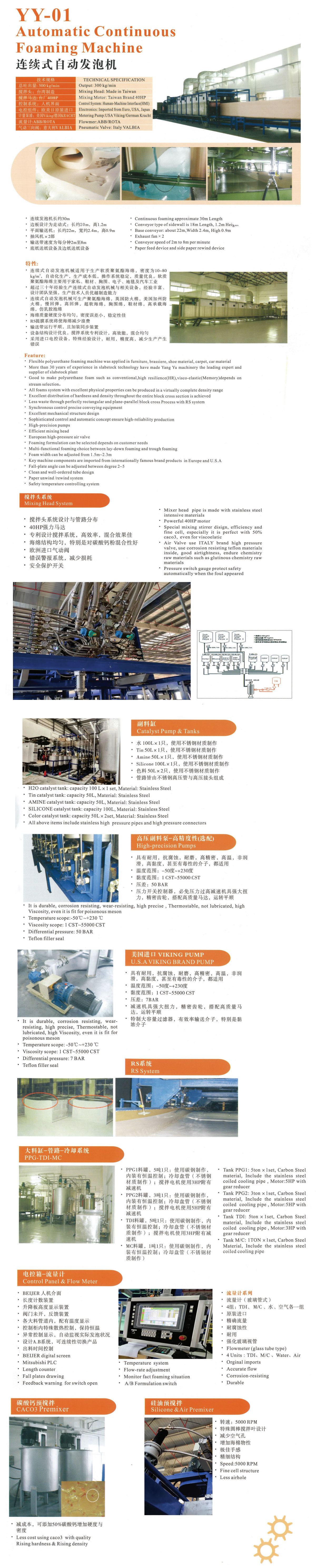

china Continuous automatic foaming line

2025-05-20

The Continuous Automatic Foaming Line represents a cutting-edge solution for the automated production of foam-based materials, enabling high-volume, consistent, and cost-efficient production. This state-of-the-art system is engineered to deliver superior quality foam products used in various applications such as insulation, automotive parts, and packaging solutions.

Feature:

●Flexible polyurethane foaming machine was applied in furniture,brassiere,shoe material,carpet,car material

●More than 30 years of experience in slabstock technology have made Yang Yu machinery the leading expert and supplier ofslabstock plant

●Good to make polyurethane foam such as conventional,high resilience(HR),visco-elastic(Memory)depends on stream selection.

●All foams system with excellent physical properties can be produced in a virtually complete density range

●Excellent distribution of hardness and density throughout the entire block cross section is achieved

●Less waste through perfectly rectangular and plane-parallel block cross Process with RS system

●Synchronous control precise conveying equipment

●Excelentmechanicalstructure design

●Sophisticated control and automatic concept ensure high-reliability production

●High-precision pumps

●Efficient mixing head

●European high-pressure air valve

●Foaming formulation can be selected depends on customer needs

●Multi-functional foaming choice between lay-down foaming and trough foaming

●Foam width can be adjusted from 1.5m~2.3m

●Key machine components are imported from internationally famous brand products in Europe and U.S.A

●Fall-plate angle can be adjusted between degree 2~5

●Clean and well-ordered tube design

●Paper unwind/rewind system

●Safety temperature controlling system

The Continuous Automatic Foaming Line represents a cutting-edge solution for the automated production of foam-based materials, enabling high-volume, consistent, and cost-efficient production. This state-of-the-art system is engineered to deliver superior quality foam products used in various applications such as insulation, automotive parts, and packaging solutions.

Key features of the Continuous Automatic Foaming Line include precise control of the foaming process, with automated adjustments made for factors such as temperature, pressure, and mixing speed. These adjustments guarantee that the foam produced meets the desired density, cell structure, and mechanical properties, ensuring that it performs well in its intended applications.

The system is highly automated, reducing the need for manual labor and human intervention. Automated material feeding, mixing, and molding processes ensure that production runs smoothly without errors. In addition, the cutting and packaging stages are also automated, offering seamless integration and faster turnaround times.

With its innovative design and robust functionality, the Continuous Automatic Foaming Line is the ideal solution for manufacturers seeking to improve productivity, reduce costs, and produce high-quality foam products with consistent performance.