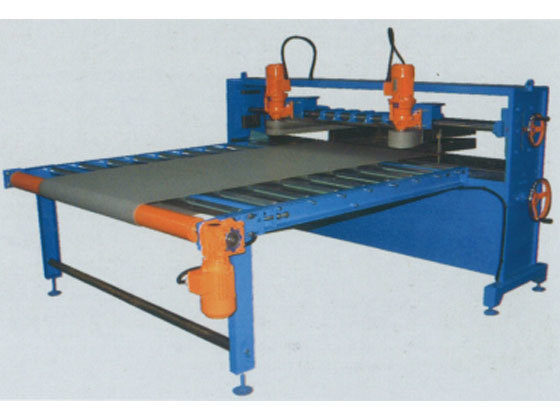

Newest Mattress Cover Filling Equipment

2025-06-18

Revolutionize your mattress production line with our advanced mattress cover filling equipment, designed to deliver precision, efficiency, and consistency in every operation. This state-of-the-art machinery automates the process of inserting and distributing filling materials—such as foam, fiber,

TECHNICAL SPECIFICATION

Thickness ofmattress: 2”~6”

Width ofmattress: 65”~86”

Belt conveyor motor:1/2HP,with reducer

Side conveyor motor:1/2HP,with reducer

Revolutionize your mattress production line with our advanced mattress cover filling equipment, designed to deliver precision, efficiency, and consistency in every operation. This state-of-the-art machinery automates the process of inserting and distributing filling materials—such as foam, fiber, or latex—into mattress covers with unparalleled accuracy. Ideal for manufacturers of hybrid, memory foam, and spring mattresses, our mattress cover filling equipment ensures uniform density and eliminates manual labor errors, significantly boosting productivity while reducing material waste.

Built for durability and performance, our mattress cover filling equipment features a robust stainless-steel frame, PLC-controlled automation, and adjustable settings to accommodate various mattress sizes (Twin to King) and filling types. The intuitive touchscreen interface allows operators to fine-tune parameters like filling speed, compression levels, and material distribution for customized results. Additionally, integrated sensors detect irregularities in real time, ensuring consistent quality and preventing over- or under-filling defects.

Safety and ease of maintenance are prioritized in our mattress cover filling equipment, with accessible components, automatic lubrication systems, and fail-safe mechanisms to protect operators. Suitable for high-volume production environments, this equipment seamlessly integrates with existing conveyor systems and can process hundreds of units per hour. By investing in our cutting-edge mattress cover filling equipment, manufacturers can achieve superior product quality, reduce labor costs, and meet growing market demands with confidence.